CTA1200

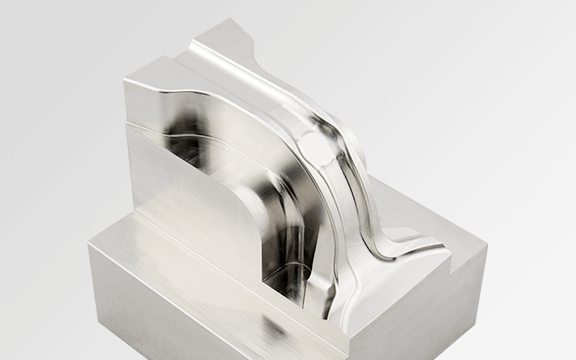

3-Axis CNC Machining Center Suitable for the Large Precision Die Mold Part Processing.

10~20μm processing accuracy stably achieved relied on JINGDIAO hardware configuration and technical support.

- X/Y/Z Travel: 47.2/31.5/13.8 in.

- Worktable Size: 49.2×33.5 in.

- Max. Load: 2204.6 lb.

- X/Y/Z Travel: 47.2/31.5/13.8 in.

- Worktable Size: 49.2×33.5 in.

- Max. Load: 2204.6 lb.

JD150S-20-HA50/C(Standard) Coolant through Spindle

JD150SC-20-HA50/A(Optional)

Highlights

Detail Design for Medium and Large Mold Processing

The spacious loading and unloading space of the front door is convenient for the hoisting, loading and unloading of large workpieces;

Side operation mode, closer to the part processing area, is convenient for operation and observation;

Spiral chip conveyors equipped on the left, right and front sides of the machine, and a chip washing device inside the machine bed, benefit rapid chip disposal.

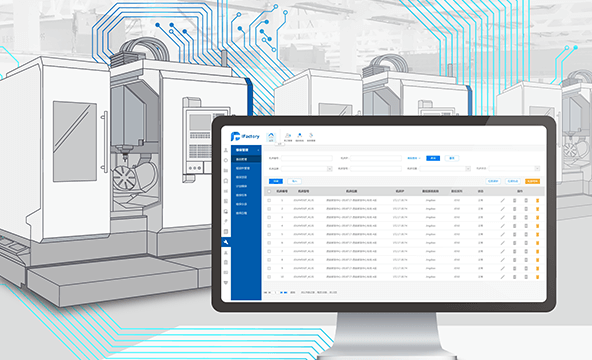

Appropriate Hardware Configuration Meet More Production Needs

JINGDIAO high-speed precision spindle has strong cutting ability and realizes the processing of quenched materials, stainless steel and other difficult cutting materials;

Filtering and chip disposal devices can be flexibly selected according to product characteristics and processing requirements.

JINGDIAO Featured Technology to Ensure Machining Quality

JINGDIAO on-machine inspection system can be used to quantify the state of machine tools, tools and workpieces in precision machining.