The company solemnly declares: Please recognize the designated official websites only, and all others are fraudulent. Avoid transactions on non-official platforms to protect the security of your personal information.

The company solemnly declares: Please recognize the designated official websites only, and all others are fraudulent. Avoid transactions on non-official platforms to protect the security of your personal information.

Recommended

{{recommends[0].title}}

{{recommends[0].description1}}

{{recommends[0].description2}}

{{recommends[1].title}}

{{recommends[1].description1}}

{{recommends[1].description2}}

{{recommends[2].title}}

{{recommends[2].description1}}

{{recommends[2].description2}}

{{recommends[3].title}}

{{recommends[3].description1}}

{{recommends[3].description2}}

Machining Samples

Jingdiao Seamless Integration

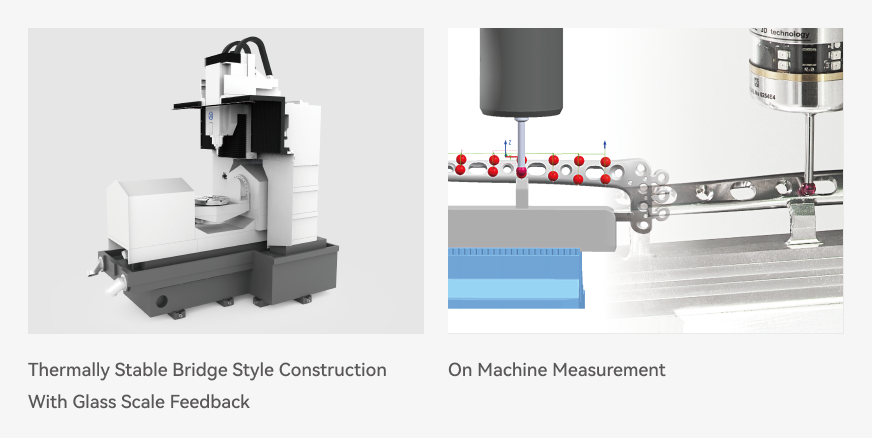

Seamless Integration Design

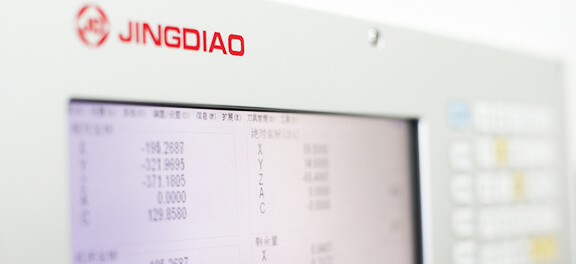

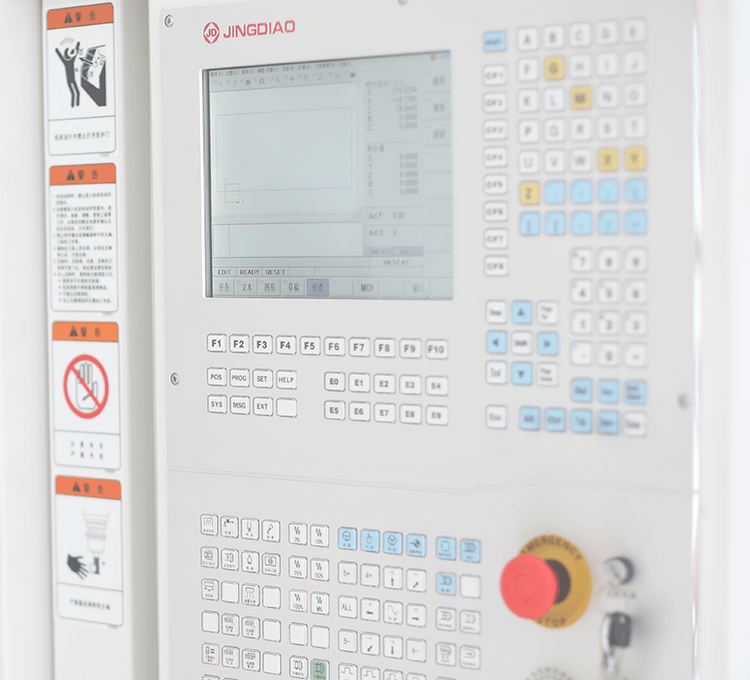

Jingdiao’s vertically integrated CAD/CAM, controller, and automation systems create a seamless manufacturing process that’s easy to operate.

When combined with our On-Machine Measurement and Intelligent Error Compensation software, the system accurately measures both the workpiece and cutting tools, then automatically compensates for errors such as alignment, material variation, and tool size deviation.

The process begins with an intelligent NC program generated in Jingdiao’s CAM software. This program is executed by the Jingdiao control system, which continuously collects data from built-in sensors. The control system analyzes this data in real time and intelligently adjusts machining parameters when necessary—ensuring highly accurate parts and exceptional yield rates.

Jingdiao’s On-Machine Measurement software functions is like having an artificial operator that will never leave you—always precise, never fatigued, and working 24/7.

When combined with our On-Machine Measurement and Intelligent Error Compensation software, the system accurately measures both the workpiece and cutting tools, then automatically compensates for errors such as alignment, material variation, and tool size deviation.

The process begins with an intelligent NC program generated in Jingdiao’s CAM software. This program is executed by the Jingdiao control system, which continuously collects data from built-in sensors. The control system analyzes this data in real time and intelligently adjusts machining parameters when necessary—ensuring highly accurate parts and exceptional yield rates.

Jingdiao’s On-Machine Measurement software functions is like having an artificial operator that will never leave you—always precise, never fatigued, and working 24/7.

Free Part Evaluation

With Jingdiao’s part evaluation our engineers will evaluate the customer’s CAD file and determine the cycle time, best machine, spindle size, options, cutting fluid, automation, best cutting tools & and fixturing in a written report. Well program the part select best cutting tools design, build fixtures & provide on-site implementation of the process.

{{aboutJingDiao.title}}

{{aboutJingDiao.description}}

Technology

The company solemnly declares: Please recognize the designated official websites only, and all others are fraudulent. Avoid transactions on non-official platforms to protect the security of your personal information.

The company solemnly declares: Please recognize the designated official websites only, and all others are fraudulent. Avoid transactions on non-official platforms to protect the security of your personal information.

Recommended

{{recommends[0].title}}

{{recommends[0].description1}}

{{recommends[0].description2}}

{{recommends[1].title}}

{{recommends[1].description1}}

{{recommends[1].description2}}

{{recommends[2].title}}

{{recommends[2].description1}}

{{recommends[2].description2}}

{{recommends[3].title}}

{{recommends[3].description1}}

{{recommends[3].description2}}

Machining Samples

Jingdiao Seamless Integration

Seamless Integration Design

Jingdiao’s vertically integrated CAD/CAM, controller, and automation systems create a seamless manufacturing process that’s easy to operate.

When combined with our On-Machine Measurement and Intelligent Error Compensation software, the system accurately measures both the workpiece and cutting tools, then automatically compensates for errors such as alignment, material variation, and tool size deviation.

The process begins with an intelligent NC program generated in Jingdiao’s CAM software. This program is executed by the Jingdiao control system, which continuously collects data from built-in sensors. The control system analyzes this data in real time and intelligently adjusts machining parameters when necessary—ensuring highly accurate parts and exceptional yield rates.

Jingdiao’s On-Machine Measurement software functions is like having an artificial operator that will never leave you—always precise, never fatigued, and working 24/7.

When combined with our On-Machine Measurement and Intelligent Error Compensation software, the system accurately measures both the workpiece and cutting tools, then automatically compensates for errors such as alignment, material variation, and tool size deviation.

The process begins with an intelligent NC program generated in Jingdiao’s CAM software. This program is executed by the Jingdiao control system, which continuously collects data from built-in sensors. The control system analyzes this data in real time and intelligently adjusts machining parameters when necessary—ensuring highly accurate parts and exceptional yield rates.

Jingdiao’s On-Machine Measurement software functions is like having an artificial operator that will never leave you—always precise, never fatigued, and working 24/7.

Free Part Evaluation

With Jingdiao’s part evaluation our engineers will evaluate the customer’s CAD file and determine the cycle time, best machine, spindle size, options, cutting fluid, automation, best cutting tools & and fixturing in a written report. Well program the part select best cutting tools design, build fixtures & provide on-site implementation of the process.

{{aboutJingDiao.title}}

{{aboutJingDiao.description}}