CTA400

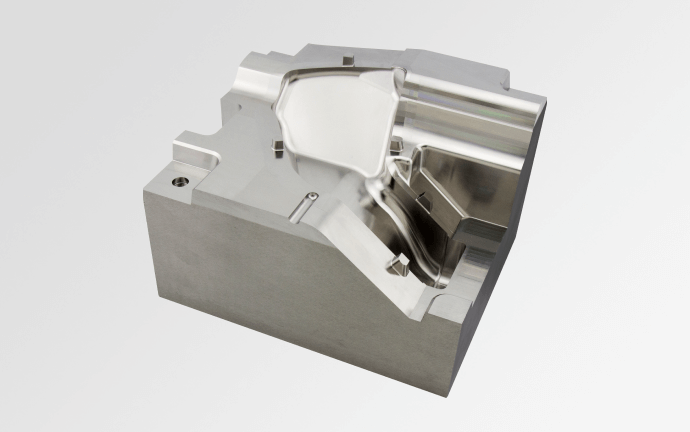

JINGDIAO CNC Machining Center is Suitable for Processing Hard Metal Materials (HRC>50) Die Mold Parts.

Meet the composite processing requirements of precision die mold parts, and stably achieve processing accuracy of 10~20μm.

- X/Y/Z Travel: 15.7/15.7/11.8 in.

- Worktable Size: 20.9×17.0 in.

- Max. Load: 661.4 lb.

- X/Y/Z Travel: 15.7/15.7/11.8 in.

- Worktable Size: 20.9×17.0 in.

- Max. Load: 661.4 lb.

Configuration 1

Configuration 2

Configuration 3

Configuration 4

Tool Magazine

Spindle Type

Spindle Specification

Umbrella Type(16 Tools)

Chain Type(37 Tools)

High-Speed Precision Spindle

JD150S-20-HA50/C(Standard) Coolant through Spindle

JD150SC-20-HA50/A(Optional)

JD150S-20-HA50/C(Standard) Coolant through Spindle

JD150SC-20-HA50/A(Optional)

20000rpm/HSK-A50

Tool Magazine

Spindle Type

Spindle Specification

Umbrella Type(16 Tools)

High-Speed Precision Spindle

JD150S-20-HA50/C(Standard) Coolant through Spindle

JD150SC-20-HA50/A(Optional)

JD150S-20-HA50/C(Standard) Coolant through Spindle

JD150SC-20-HA50/A(Optional)

20000rpm/HSK-A50

Tool Magazine

Spindle Type

Spindle Specification

Chain Type(37 Tools)

High-Speed Precision Spindle

JD150S-20-HA50/C(Standard) Coolant through Spindle

JD150SC-20-HA50/A(Optional)

JD150S-20-HA50/C(Standard) Coolant through Spindle

JD150SC-20-HA50/A(Optional)

20000rpm/HSK-A50

Highlights

Control Small Changes in Key Machining Elements to Achieve Stable High-Quality Processing

Select the appropriate software and hardware configuration can stably achieve precision machining of 10-20μm;

Equipped with on-machine inspection system to quantify the status of machine , tools and workpieces in precision machining;

Equipped with JINGDIAO MQL to meet the cooling requirements of micro-milling.

A Variety of Optional Configurations to Meet Different Processing Needs

Various types of JINGDIAO spindles are available;

The 37-capacity tool magazine can be equipped to meet the needs of multiple tools in composite processing;

Reserve the automation interface, which can realize automatic processing.