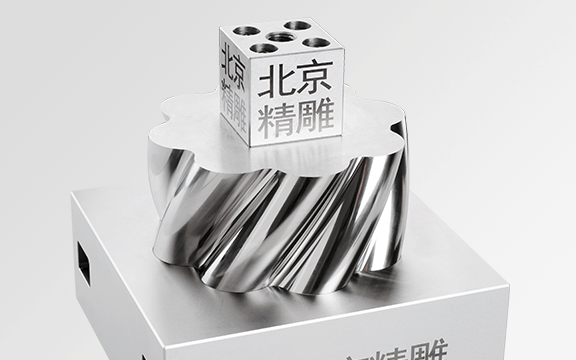

GRA400

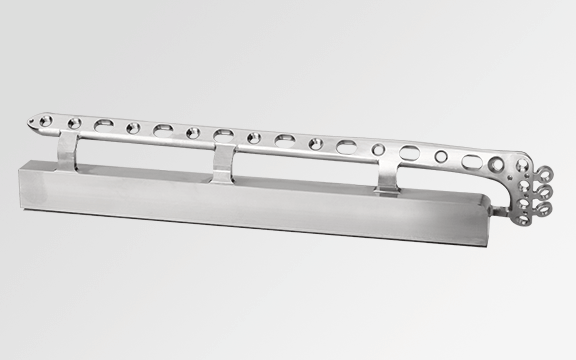

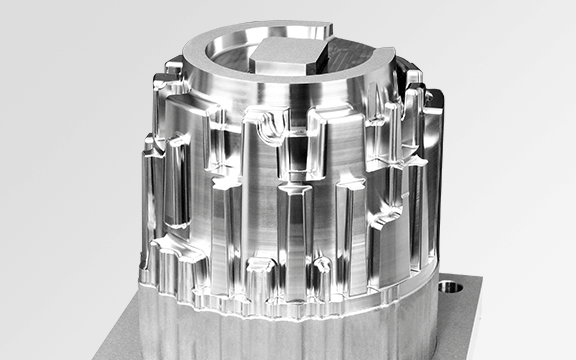

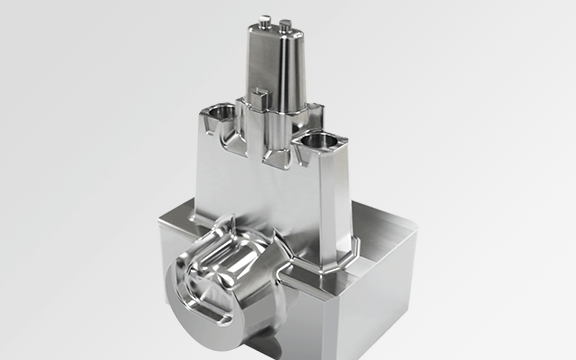

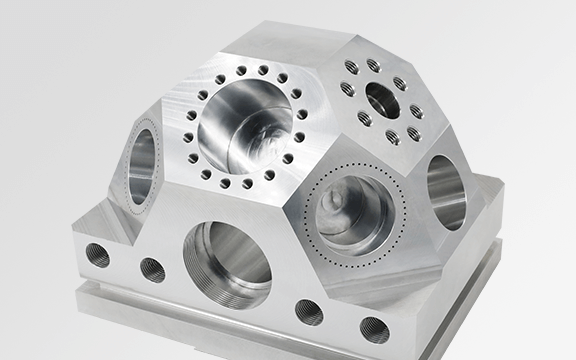

Precision Type JINGDIAO 5-Axis High-Speed Machining Center Suitable for Precision Machining Such as Drilling, Milling and Grinding of Complex Shape Metal Hard Materials (HRC > 50).

JINGDIAO high-speed precision spindle with torque of 21.5Nm is a standard component for GRA400, which meets the needs of using a wide range of tools to realize composite machining such as milling, grinding, drilling, boring and tapping and achieve 2 ~ 10 μm machining accuracy stably.

- X/Y/Z Travel: 17.7/26.8/15.7 in.

- A/C Rotation Range: -120°~90°/360°

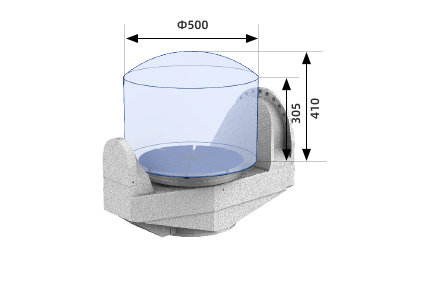

- Worktable Size: Ф15.7 in.

- Workload: 330.7 lb.

Max. Workpiece Dimension Unit: mm

Max. Workpiece Dimension Unit: mm

- X/Y/Z Travel: 17.7/26.8/15.7 in.

- A/C Rotation Range: -120°~90°/360°

- Worktable Size: Ф15.7 in.

- Workload: 330.7 lb.

JD150S-20-HA50/C Coolant through Spindle

JD150SC-20-HA50/A

Highlights

Micron Machining Capability

Achieve “0.1 μ feed, 1 μ cutting, nanoscale surface roughness” machining effect stably;

JINGDIAO high-speed precision spindle is equipped as standard, and the torque is up to 21.5nm, which can meet the needs of a wide range of tools in precision mold machining, such as, using large-diameter face milling cutter to process large surface finishing;

Coolant through spindle is optional, which is suitable for deep hole and deep cavity processing.

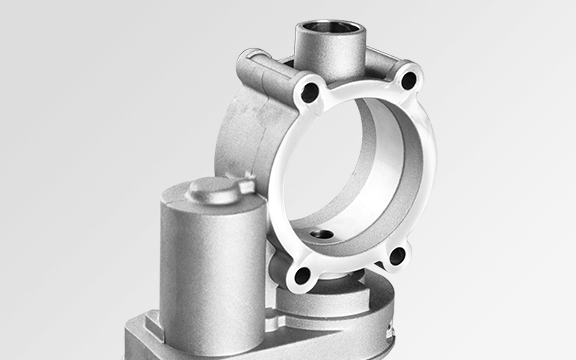

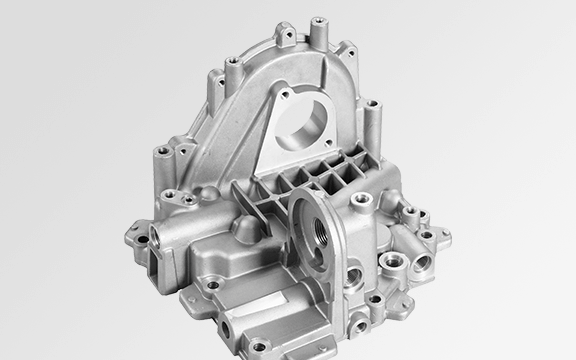

Meet the Working Condition Requirements of Batch Production

JINGDIAO high-speed precision spindle is equipped as standard, which can achieve composite processing such as milling, grinding, drilling, boring and tapping;

Using JINGDIAO high-speed precision spindle for side milling and cycloid machining to ensure the machining efficiency;

Rotary table hydraulic fixture interface is optional, and cooperates with automatic hydraulic fixture to complete the rapid clamping of workpieces to meet the efficient processing needs of batch production;

The in-machine spray system can be installed to cooperate with the screw chip conveyor in the machine to quickly clean the chips;

Scraper style chip conveyor is optional to collect a large amount of chips to the chip collecting trolley, so as to prolong the chip cleaning cycle for parts batch machining.

Stable Machining Quality

JINGDIAO on-machine inspection system can be used to quantify the state of machine tools, tools and workpieces in precision machining.