QUICK-CHANGE CLAMPING SYSTEM

Realizing Fast, Accurate and Efficient Clamping

Equipped with standardized interface, JINGDIAO quick-change clamping system can be connected with vise, permanent magnetic chuck, customized fixture and so on. You can use them in any combination to fulfill variety of machining needs including multi-axis machining, multi-process machining, automation and measurement.

QUICK-CHANGE

CLAMPING SYSTEM

Quick-change Clamping System

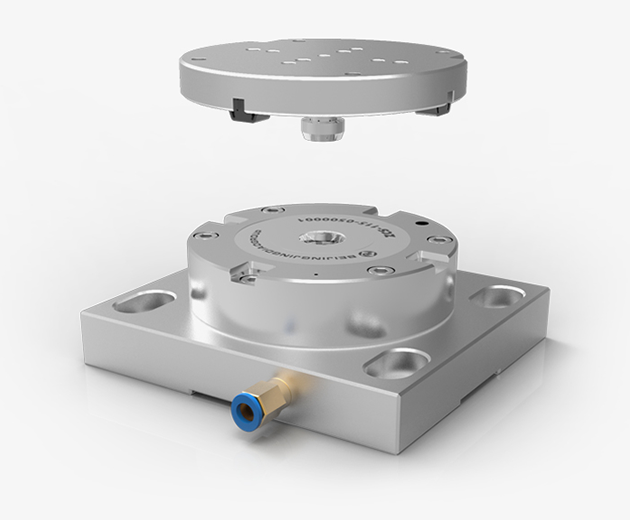

Regular quick-change clamping system

Basic Specification

| Repetitive Position Accuracy: 3μ |

| Workpiece Size: 150*150mm |

| Workload: 12kN |

| Unlocking Pressure: 0.5MPa |

| Weight: 1.85kg |

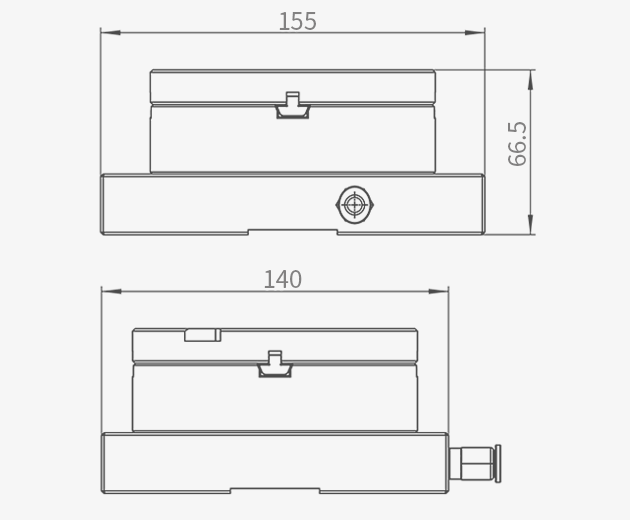

Dimension

Product Instruction

Basic Specification

| Repetitive Position Accuracy: |

| Workpiece Size: |

| Workload: |

| Unlocking Pressure: |

| Weight: |

Dimension

Product Instruction

Basic Specification

| Repetitive Position Accuracy: |

| Workpiece Size: |

| Workload: |

| Unlocking Pressure: |

| Weight: |

Dimension

Product Instruction

Basic Specification

| Repetitive Position Accuracy: |

| Workpiece Size: |

| Workload: |

| Unlocking Pressure: |

| Weight: |

Dimension

Product Instruction

Basic Specification

| Repetitive Position Accuracy: |

| Workpiece Size: |

| Workload: |

| Unlocking Pressure: |

| Weight: |

Dimension

Product Instruction

Basic Specification

| Repetitive Position Accuracy: |

| Workpiece Size: |

| Workload: |

| Unlocking Pressure: |

| Weight: |

Dimension

Basic Specification

| Repetitive Position Accuracy: |

| Workpiece Size: |

| Workload: |

| Unlocking Pressure: |

| Weight: |

Dimension